Biology Inspires a Plastics (R)Evolution

Long before humans inhabited the Earth, pristine ecosystems were replete with “plastic”.

Wait. What?

According to Miriam-Webster’s dictionary, plastic generally means materials that are “capable of adapting to varying conditions; pliable.”

With that in mind, take a fresh look at the natural world around you. Organisms, from plants and insects to reptiles and mammals, are a Paris-transcending fashion show of “plastic” materials in an astounding array of designs–designs that not only look beautiful, but serve the same set of functions we demand of our synthetic, commercial plastics. Although synthetic plastics are associated with the modern industrial age, the functions they serve are as old as life itself. Organisms abound with light-weight materials that hold liquids, protect from impact, communicate through visual cues, preserve what’s inside by managing oxygen, moisture, microbes, and so on.

Behold nature’s materials. There are squishy ones, like the slimy mucus secreted by slugs that enable the appendage-less critter to move along a solid surface. The mucus reversibly alternates between semi-solid and lubricating liquid states depending on the amount of pressure exerted on it by the contractions of the slug. Slug mucus “plastic” is largely water, but it’s also made up of proteins, carbohydrates, and minerals.

Banana slug

Soft, stretchy materials, like mammalian skin allow for unrestricted movement, manage moisture in and out of the body, protect from microbes, self-heal, and enable a sense of touch. Skin “plastic” is largely made of collagen, other proteins, carbohydrates, fats, and water.

Elephant skin

Flexible materials, such as leaves, regulate moisture and gases in and out of the plant, protect from environmental factors, and harvest energy from sunlight to produce sugar and an array of other useful compounds. Leaf “plastic” is largely made up of cellulose, other carbohydrates, proteins, polyphenols, minerals, and water.

Ginko leaves

Rigid materials, such as beetle exoskeletons, manage moisture in and out of the organism, protect from impact, predators and microbes, and provide a surface for visual signaling. Exoskeletal “plastic” is primarily made of chitin, along with other carbohydrates, proteins, minerals, and water.

Beetles

Hard materials, such as seashells, protect from impact, cracks, and predators. Seashell “plastic” is mostly made of calcium carbonate mineral crystals, but also contains proteins, carbohydrates, and water.

Seashell

Ironically, today's commercial plastics were borne of an effort to replace the use of biological “plastic” materials in the mid 19th and early 20th centuries. Celluloid (a chemically altered form of cellulose) was invented to replace ivory used for billiard balls. Bakelite, the first synthetic plastic derived solely from non-biological inputs, was invented to replace shellac used as an electrical insulator, and nylon was invented during WWII to replace silk. The economic boom of post WWII America led to a dramatic rise in the demand for cheap, synthetic plastics. “Humans are now using a million plastic bottles a minute, and 500 billion plastic bags a year.” (source: Planet Plastic). Where does all that plastic go when we’re done using it?

Ocean plastic pollution was first documented in the 1960s during a decade in which the impact of unbridled industrial expansion betrayed the false assumption that “dilution is the solution to pollution.” Rachel Carson documented the impact of pesticide use and climate change (yes, even back then) on wildlife; Ohio’s polluted Cuyahoga River caught fire multiple times; carelessly buried chemical wastes percolated into the basements of suburban homes in Love Canal, New York; major US cities were choking on smog, and leaded gasoline was blanketing the nation with the toxic element. While the advent of environmental regulations helped reverse many of those ills, conventional synthetic plastics have continued their rise.

Today we know that even the vast volume of the world’s oceans is not enough to dilute decades of continued conventional plastics manufacture, use, and disposal. Images abound of the plastic gyres in all the world's oceans and the impact it’s having on wildlife.

The Great Pacific Garbage Patch (Ray Boland, NOAA)

Dead albatross with ingested plastic. (Chris Jordan, U.S. Fish and Wildlife Service)

The good news is, we’re poised to bring the story full circle–to turn back to nature as model, mentor, and measure of how to evolve from conventional plastics to novel, bio-inspired materials that provide the functional characteristics we need while being in sync with nature.

Like industry, nature relies on chemistry for making, using, and managing her materials, but unlike industry, her chemical processes and materials not only side-step pollution throughout their life cycle, they create conditions conducive to life. Natural “plastics” break down to starting materials that nurture the very ecosystems that created them in the first place.

Soil

How is it possible that nature can make materials that are both high-performing and life-friendly? The answer is two fold:

Two key principles underlying nature’s high-performing, life-friendly materials

Composition: nature uses about 30 elements on the periodic table whereas industry uses more than twice that number to achieve the same functions. As evidenced above, almost all of nature’s materials, from hard shells, to flexible leaves, to soft tissue, are composites of protein, carbohydrate, mineral, and other biopolymers. The relative proportion of the ingredients contribute to overall material functionality, and

Architecture: instead of relying solely on chemistry, nature relies heavily on sophisticated and elegant microscopic, hierarchical 3D structures to achieve functionality through varied arrangements, distributions, dimensions, and orientations of building units.

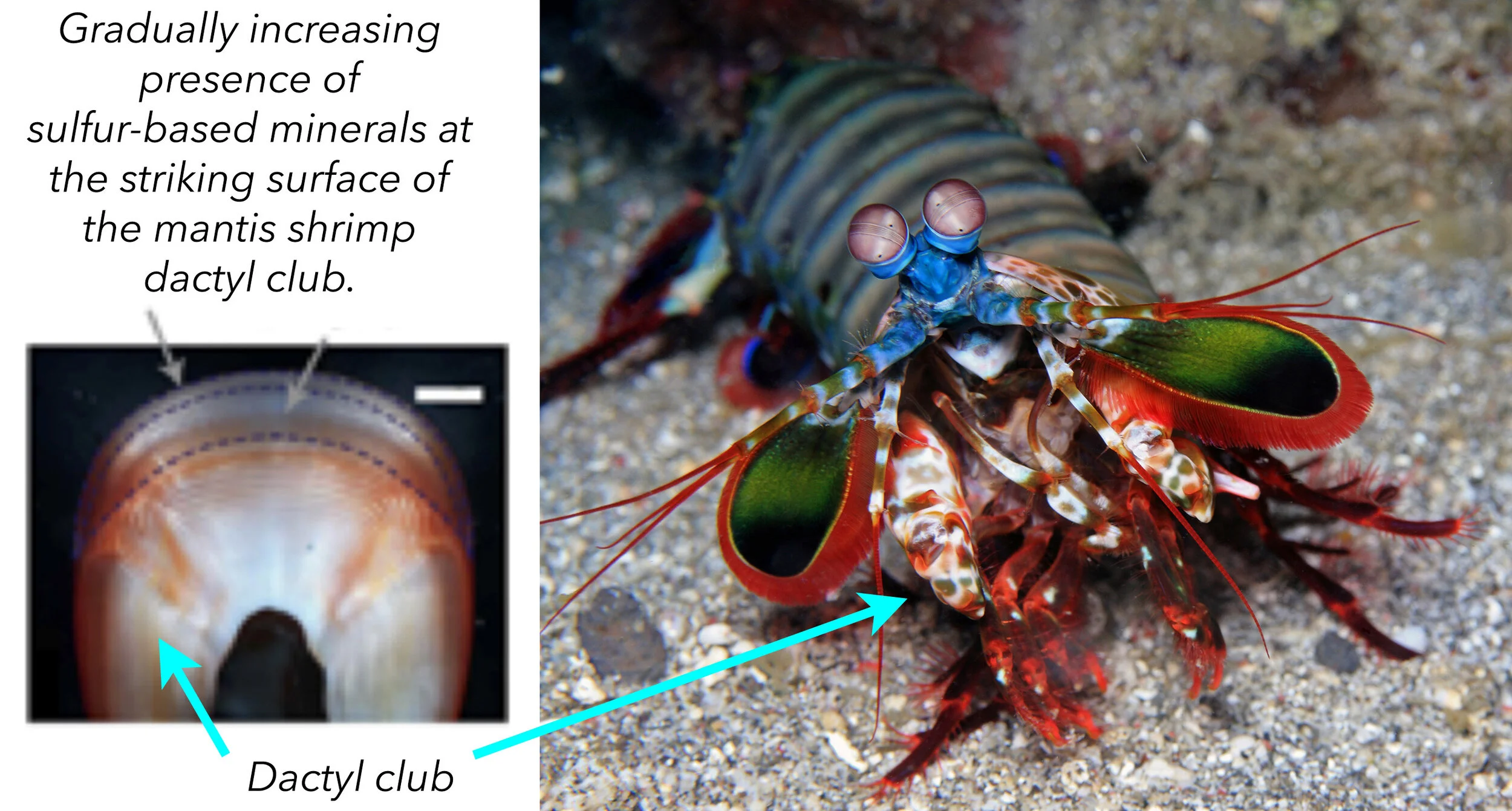

While man-made materials are often uniform throughout its dimensions, nature’s materials often exhibit gradients where the composition and/or the architecture change at different points within a single material to meet needs at local sites. For instance, there is a gradually higher concentration of sulfur-based minerals towards the striking face of the mantis shrimp’s dactyl club imparting increased hardness and toughness at the point where the club strikes the intended prey.

Mantis shrimp dactyl club

A microscopic view of the cross section of a plant stem clearly shows an architectural gradient. The density and diameter of cells, their orientation (i.e., parallel or perpendicular arrangement relative to the exterior surface), and the layer thickness vary across the stem’s diameter. Together, this non-uniform architecture of cells gives rise to the stem’s structural strength, ability to bend without bucking, and other characteristics.

Cross section of a plant stem

Within the thickness of half a millimeter (about the width of 4 human hairs) a weevil’s exoskeleton is composed of many layers of largely the same material (primarily chitin). Together, the varying thickness of each layer and the alternating directions, diameters, and orientations of the chitin fibers impart the exoskeleton with the ability to protect the organism’s internal contents from impact, manage moisture and gas exchange, and send a colorful message to the outside world. By using the same biodegradable material throughout, the beetle’s exoskeleton decomposes at the end of its useful life, returning its nutrients to the soil.

Flexible film packaging used by the food and consumer products industries to keep food, cosmetics, and other consumer goods fresh and intact, serve many of the same functions as the beetle exoskeleton. Industry achieves those functions by gluing together layers of disparate materials such as plastic, foil, and paper–each material serving a single function. While individually, these materials can be recycled, once bonded together, recycling is all but impossible due to the difficulty of separating the thin layers, so they end up in landfills–or if carelessly discarded, perhaps eventually end up in the ocean.

What types of new innovations in packaging, or other applications of conventional plastics, could be achieved by looking at the principles behind multi-functional insect coverings and nature’s other time-tested materials?

Cross section of a weevil’s exoskeleton

Usher in a (r)evolutionary biomimetic plastic materials system

Given how much nature does with proteins, carbohydrates, other biopolymers, and minerals as building blocks for all of its “plastic” materials, maybe we don’t need a new engineered polymer in order to invent a new generation of high-performing life-friendly plastics alternatives. Feedstocks abound in many industrial waste streams–chitin from the shellfish industry, keratin from chicken feathers, cellulose from pulp, paper, and lumber, etc. We can put them to use as feedstocks in a new biomimetic plastic materials system that produces new materials based on nature’s design principles.

We’re at a sweet spot where knowledge, technology, and creativity merge. Advanced microscopes and other analytical tools are increasing our detailed understanding of how the natural world works–biomimicry is a systematic approach to tapping into that knowledge base and translating nature’s design principles into new problem-solving concepts. Additive manufacturing–of which 3D printing is just the tip of the iceberg–is enabling humans to manufacture hierarchical materials from the bottom up with greater dexterity, just like nature does. Computer power is enabling researchers to rapidly test new biomimetic ideas in silico so that inventors can choose the most promising ones to test at the lab bench. Now is the time to shake up the plastics status quo!

Covid-19 has brought world economic activity to a halt and is allowing the natural world to rebound. As we restart the economy, let’s honor nature’s mentors and learn to create industrial systems that benefit both human society and the ecosystems that nurture us.